PET solutions

planning/designing

Optimization

Financial solutions

Maintenance

Practical training

Models

SOFT DROP System for PET preforms storage

SOFT DROP System for PET preforms storage

SOFT DROP System for PET preforms storage

Since 1991, MB Conveyors has produced a very efficient system to eliminate damage caused to PET preforms during storage inside the container.

The operating principle of the Soft Drop: the moulding cycle is received from the IMM and conveyed by means of a CPT conveyor to the PA conveyor/distributor installed for the programmed filling of hoppers/lowerators.

When the loading phase ends, the hopper descends into the storage container and, using an ultrasound sensor, releases the preforms at a minimum predefined height. This release height remains constant throughout the container filling phase. When the first container is filled, filling of the second container begins, while an acoustic-visual alarm warns the operator that the filled container must be replaced with an empty one.

MAIN TECHNICAL FEATURES:

- Dimensions of containers for standard Soft Drop: base 1000 x 1200 x h. 1200 m

- Standard Soft Drop complete with control panel

- Main implementations of Soft Drop:

– quality control by weighing with tolerance 0 to + 12 preforms per container

– installation of vibrating platforms

– construction of loading conveyor complete with cooling device

T-CONVEYOR PET preforms storage line

T-CONVEYOR PET preforms storage line

T-CONVEYOR PET preforms storage line

The T-Conveyor is a widely used solution in the PET sector for the storage of preforms in containers. Compared to the Soft Drop, this solution does not include the hoppers descending into the container and is therefore proposed when it is sure that there is no possibility of damage to the preforms as they drop from the PA conveyor into the container.

The CP conveyor receives the preforms from the production unit outlet and conveys these to the PA distributor which unloads these according to a predefined logic into two storage containers.

The control panel, if requested complete with PLC, controls the filling logic.

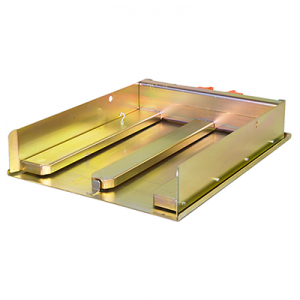

PV - vibrating platform

PV – vibrating platform

PV – vibrating platform

The vibrating platforms produced by MB are an essential accessory to optimize the storage capacity of the containers where the product is stored, and to eliminate its central accumulation ( pyramid effect ).

MB vibrating platforms find their standard application in the PET preforms production, where they can be integrated into complex filling systems as Soft Drop or TConveyors.

An appropriate setting of the intervention timing of the platform during the filling process can result in an increase of the capacity of the container from +5 to + 12/15 %

- MB vibrating platforms are made of sturdy, bended and welded metal sheet, fully treated with zinc – plating process

- A variable intensity vibrator determines the vibrations necessary for the optimization of the containers’ filling

- MB vibrating platforms are suitable for containers with the following dimensions : base 800/1000 x 1200 mm and maximum height 1350 mm (pallet included)

Categories

Conveyors

Separators

Elevators

T50 Compact

Conveyors line

Cooling

Storage

Food and Pharma

Metal detector

Plastic and metal belt

PET solutions

Top control

Since 1985

MB Conveyors has more than 30 years of tradition and experience in mechanical industry and production of conveyor belts. The main qualities of the company are systemic functionality and profitability, commitment to clients, research and development with the support of experts.

Product quality is ensured through meticulous testing in all production steps along the line, with the use of most up-to-date production systems and materials of superior quality.

About the company and its products (PDF 25.2 MB)

Business lines

Automotive

medical

packaging

technical molding

teletronics

ENERGY EFFICIENCY

Energy efficiency is a concept that in our part of the world became important towards the end of 2008 and the beginning of 2009, at the outset of the world economic crisis. Most business people had, until then, mostly declaratively considered power consumption as a significant element of the total cost analysis. In these considerations, the impact of energy efficiency on the environment pollution had hardly been tackled at all.

Neofyton was among the first companies in Serbia and the region to start actively demonstrating the importance of energy efficiency, both by cutting production costs and therefore increasing profit rates and building awareness of the resource shortage and broader ecological principles.

Energy savings through the use of Neofyton's machines

In comparison with our direct competitors in the field of plastics injection machines, and with the utilization of standard hydraulics with integrated so-called "smart" pumps, our machines consume as much as 50% less energy. The use of servo-hydraulics opens up the potential of savings as high as 70%. We have a very precise power consumption measuring device to prove this.

The company Engel was the first plastics injection machine manufacturer back in 2009, which introduced the power consumption page as a standard component of the control assembly – "Ecograph", where - next to the weight of each product (molded part) in every cycle - total hourly consumption is shown, as well as the specific power consumption per one kilogram of processed plastics (kWh/kg).

ENVIRONMENTAL PROTECTION

The equipment we represent contributes to ENVIRONMENT PROTECTION in several ways.

When it comes to ancillary equipment, above all water chillers by our supplier Eurochille, used for temperature control of both hydraulics and machine servo motors and molds (tools) in which finished products are made, the chiller systems we sell facilitate the use of a new cooling system based on the so-called "adiabatic effect".

In summer, the hydraulics and servo motors of the injection molding machines call for cooling with water at a maximum of 28°C. Using the so-called "free cooling" device with the "adiabatic effect", cooling of process water is performed without cooling compressors (which use freon as the heat exchanger). Heat exchange, i.e. cooling happens exclusively by the use of ventilators, which translates into six- to eightfold savings compared to traditional chillers that use freon-based compressors.

One of our customers has reduced the required cooling energy by 1.400.000 kWh per year, i.e. by about 70.000 EUR, using the "adiabatic" cooling devices. An additional benefit is the elimination of major pollution risks which might arise from emissions of freon into the atmosphere due to tube puncture or breakage.

A similar calculation can be applied to our Engel injection molding machines, as well as to the Piovan granulate dryers.

Neofyton – partner of MB Conveyors

Neofyton is MB Conveyors’ partner for the markets of Serbia, Bosnia and Herzegovina, Macedonia, Nigeria, and Cameroon.

FSRV PLUS independent spiral roller separator – a new generation separator, designed to improve performances of the traditional spiral roller and to achieve particularly precise and efficient separation of the product from the sprue.

Neofyton youtube chanel