With the initiative Be the first. Be efficient. we offer you the answer to surging electricity prices.

Your situation:

Energy prices are rising, electricity suppliers are adjusting their tariffs upwards. But you as a company cannot raise your prices overnight. Under certain circumstances, this will destroy your calculations.

The solution from ENGEL:

We don’t just look at the injection moulding machine, but the entire plant. The combination of temperature control, intelligent device communication and smart process control leads to maximum efficiency of your system. In this way, the power consumption and CO2 emissions of your injection moulding machine can be reduced by up to 67 %. Depending on the application and machine.

What is the power consumption of an injection moulding machine?,

Often the power consumption of the injection moulding machine is less than 50 % of the total consumption of the injection moulding plant.

For this reason, the injection moulding system must be considered as a whole when looking at energy. High efficiency is already a matter of course with new injection moulding machines from ENGEL. Our drive is to find the most efficient solution for your requirement. With integrated temperature control solutions as well as intelligent device communication, up to 67 % electricity and thus CO2, can be saved. In addition, there are other technical constraints, such as accessibility, precision requirements or available space, which must be taken into account. An overall view is necessary to find the best solution for you and to reduce the power consumption and CO2 emissions of your injection moulding machine. For this reason, ENGEL presents its Green Fleet and our efficiency packages.

Further reduce the power consumption of your injection moulding machine

As the above chart shows, ENGEL injection moulding machines are already masters at saving electricity. Our engineers and developers have already greatly reduced the power consumption of ENGEL injection moulding machines in recent years. Servo-hydraulic machines already consume less than 60% of a hydraulic injection moulding machine with a variable pump. With all-electric injection moulding machines, power consumption can be more than halved on average.

In order to provide you, the customer, with even more efficient injection moulding machines, we have defined efficiency packages. These packages, consisting of integrated temperature control and intelligent assistance systems, manage to reduce the power consumption of your injection moulding machine by a further 20 % on average.

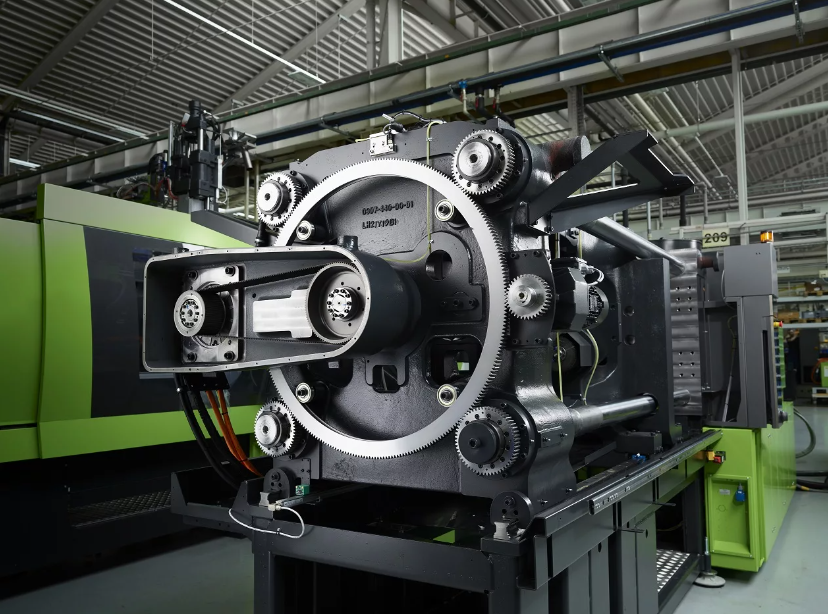

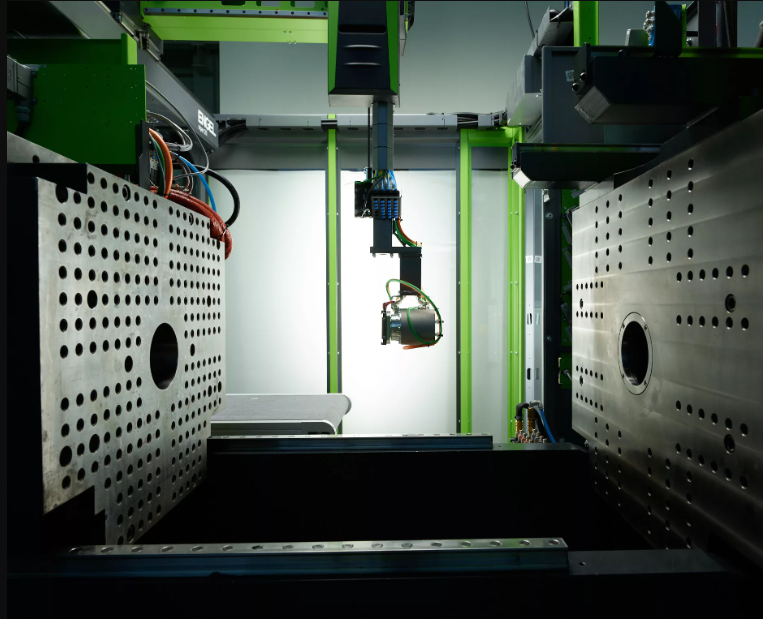

Maximum efficiency with the highest precision – our all-electric

ENGEL’s all-electric machines feature modern drive technology. Maximum efficiency is ensured, and the power consumption and CO2 emissions of your injection moulding machine are reduced. Highly dynamic servo motors in combination with friction-optimised ball screws form the core of our all-electric machines. The latest generation of our e-mac series has the shortest toggle lever on the market, resulting in a very compact design. The e-motion is specially designed for fast applications to get even more out of your application.

the fully electric one for 90 % of all applications

our all-electric e-motion for high-end applications

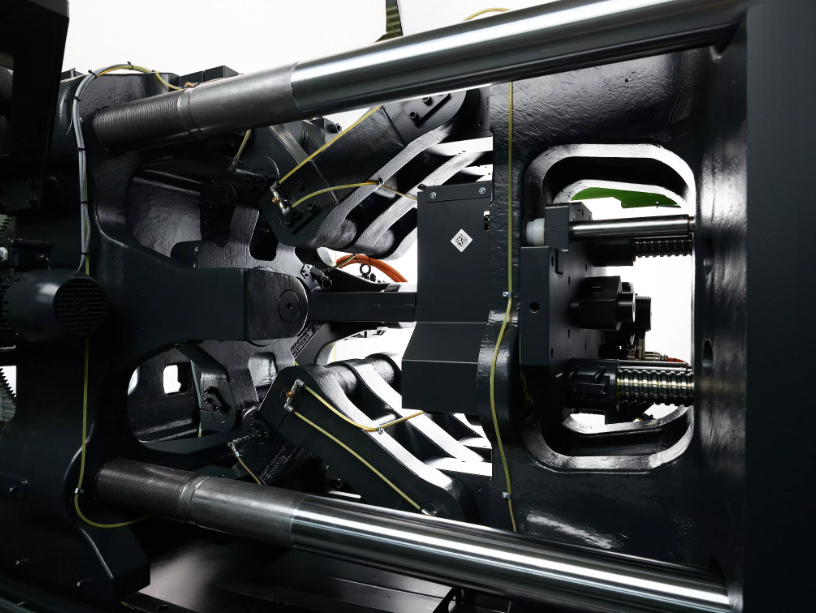

Maximum flexibility with high efficiency – our servo-hydraulic machines

The unbeatable advantage of our victory series is the tie-bar-less clamping unit. Only in this way can the machine offer maximum flexibility in terms of mould sizes, accessibility and application. If even more space is required, then our 2-platen machine of the duo series comes into play. Here, there are no compromises in terms of mould space and application. Both series are equipped with our power-saving drive ecodrive. Even in the standard version, this reduces power consumption and CO2 emissions by more than 40 % compared to a hydraulic injection moulding machine with a fixed displacement pump.

tie-bar-less for efficiently produced technical parts

the powerful injection moulding machine for large parts

Would you like to reduce the power consumption of your injection moulding machine?

Our experts will be happy to help you and calculate the savings in your specific application together with you.

Save another 20 % electricity with efficiency packages from ENGEL

The topic of saving electricity in injection moulding machines is more topical than ever. The efficiency packages developed especially for you include temperature control solutions as well as intelligent software solutions from ENGEL, with the help of which you can further savings potential can be exploited.

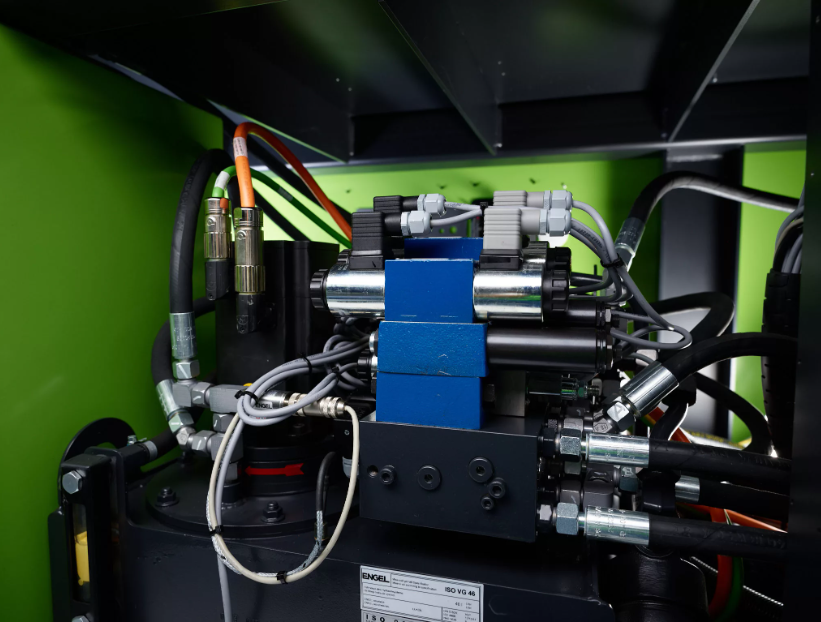

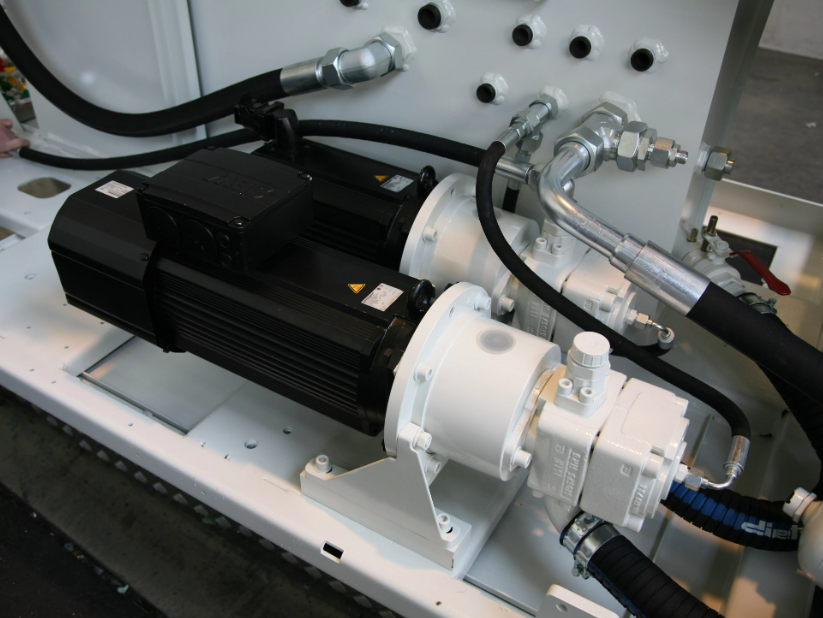

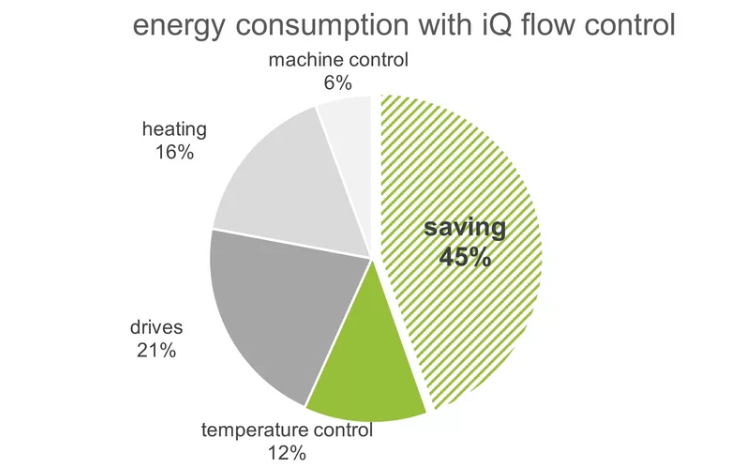

The savings potential for temperature control is huge. That is why we at ENGEL have developed the best integrated temperature control solution on the market for you. Only the combination of intelligent software, iQ flow control, the in-house flow control system e-flomo and our own temperature control units e-temp enables massive energy savings.

Only if the machine understands how much temperature control is really needed and can communicate this to the right equipment, there is a strong potential to reduce the power consumption of your injection moulding machine.

This is how you manage to operate probably the most efficient machine system on the market.

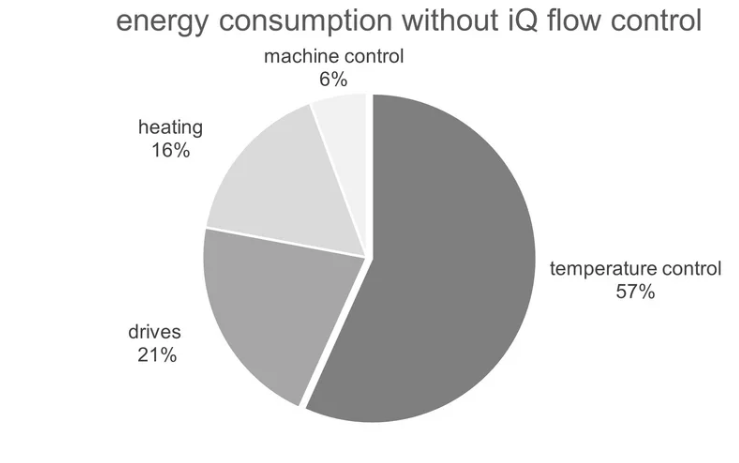

Energy consumption of an injection moulding system – example application: e-motion 170/80TL, material: PP, shot weight 30.3 g, 2 temperature control units e-temp H8 flow temperature 35°C, cycle time 30 s.

The intelligent assistant in the field of mould temperature control

The control centre for optimum cooling water supply

Perfectly tempered water for minimum energy loss