Surfaces with integrated functions are becoming more present in our everyday lives. We ask Michael Fischer, Business Development Automotive, what impact smart user interfaces are having in the automotive industry and how much potential there is.

What are smart panels and what benefits do they offer the end user?

Smart panels have become an integral part of our everyday lives. In building management, for example, smart panels can be used for energy management by enabling the control of lighting, heating and other systems based on environmental conditions or occupant preferences. In the automotive industry, individualisation, comfort and safety play a central role. Smart panels allow car owners to customise their vehicle to their personal style and preferences and increase road safety.

In the exterior area, smart panels enable the integration of customisable elements such as dynamic lighting designs that can change colour and pattern. Such technologies also offer opportunities for new types of displays such as welcome messages or status displays that can be shown directly on the body of the car. For example, the display of the battery charge level in electric vehicles.

In the interior area, customisation considerably expands the possibilities for interior design. Smart panels can be used to equip elements such as the dashboard, centre console or interior door panels with interactive surfaces that react to touch and can integrate various functions such as lighting, information or even entertainment. Users can change the colours and appearance of these elements to suit their mood or desired ambience.

How are smart panels produced by injection moulding and what benefits does the manufacturer derive from this?

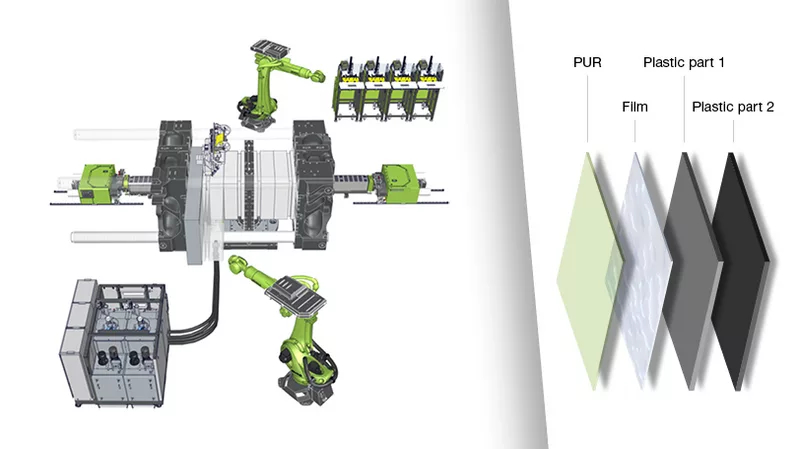

Depending on the application and use of smart panels in automotive exteriors and interiors, injection moulding offers many possibilities for the production of smart panels. Everything is possible, from back-injection of films in standard injection moulding to multi-component injection moulding with integrated films and flooding with polyurethane to produce scratch-resistant surfaces.

The use of suitable injection moulding processes plays a central role here:

- combimelt: direct production of assembly elements by combining two or more plastic materials

- foilmelt: offers design freedom by simply changing the film design. Integration of electronics into the film is also possible

- clearmelt: Flooding of surfaces directly in the process with a scratch-resistant and UV-resistant layer of polyurethane. The downstream painting line is not required

The following applies to all injection moulding processes: at the end of an injection moulding cycle, there is a finished component that can be installed directly in the car.

ENGEL systems enable the production of smart panels in a continuous process. This results in greater efficiency and cost-effectiveness, as there is no need for extensive post-processing lines or painting lines.

How are the systems for manufacturing smart panels organised in practice?

Specific machine and automation solutions are used depending on which properties the smart panel needs to fulfil. The system or layer structure is always adapted to the end product.

Such a layer structure is clearly demonstrated using the example of a “rear-end cover”:

- A decorative foil is back-injected with a dark plastic using the ENGEL foilmelt process.

- In the subsequent combimelt process, a second, transparent thermoplastic layer is produced, which enables the subsequent integration of lighting elements.

This not only allows complex geometries to be reproduced in an injection moulding cycle, but also simplifies the subsequent assembly of the components. For example, through the simultaneous production of assembly devices such as retaining lugs and the like. The film design can also be easily exchanged, which offers considerable advantages in terms of design freedom and customisation.

Is there a limit to the injection moulding machine when it comes to producing smart panels?

The size of the component determines the size or tonnage of the machine. The two-platen machine duo in particular is the best choice for the production of smart panels. With a standard clamping force range of up to 5,500 tonnes, large components can be produced. However, significantly larger machines have also been built for customers. The ENGEL duo is also ideally prepared for all injection moulding processes.

Reliable partners in the areas of mould making, film production and material supply are just as crucial as the injection moulding machine. ENGEL cooperates with renowned companies in these industries and has built up a robust network over the years. Customers receive support from the initial concept to the production of the first parts and beyond. This enables us to respond precisely to the specific needs of our customers.

In order to offer customers the opportunity to test or sample complex parts and processes, ENGEL provides a duo 5.500 combi M with a clamping force of 55,000 kN at its customer technology centre in St. Valentin. This machine is equipped with three injection units and is prepared for various injection moulding processes. Moulds with a total weight of up to 150 tonnes can be assembled. The system was completed in summer 2024. The first customer trials have already been scheduled. This will make a clear statement about ENGEL’s high level of expertise in the production of complex large components and the high degree of customer orientation that we comprehensively support on the way to realisation.

In which direction are smart panels continuing to develop and what potential is still untapped?

The future of smart panels is promising, especially in the context of increasing digitalisation and technologisation in various industries. Smart panels can increasingly be equipped with advanced technologies such as OLED displays and sensors. Interactive surfaces are also conceivable. These would enable even more comprehensive and seamless interaction, for example through gesture-based control or panels that react to environmental changes such as light and temperature.

This would also make future smart panels even more customisable, with changeable designs or displays that dynamically adapt to the user’s preferences or external conditions. This will not only increase user-friendliness, but also efficiency.