With authentig from ENGEL, transparency in production becomes a reality. The MES provides real-time information for data-driven decisions and flexible adjustments. Find out how customers benefit from seamless traceability and process optimisation.

The Manufacturing Execution System (MES) authentig from ENGEL is the answer to the growing demands of modern production environments. Whether complete traceability, transparency across all shifts or continuous process optimisation – authentig provides crucial information in real time and enables companies to make informed decisions.

In four short videos, ENGEL customers and partners document their experiences with authentig – from the introduction of the system to concrete results in everyday production.

Digital information flow and efficient process analyses

What were the challenges before the introduction of authentig? In this video, the interviewees from ENGEL describe how accessing relevant information during the night shift was challenging and how authentig now enables an improved flow of information and in-depth process analyses. In the automotive sector in particular, end-to-end traceability has become increasingly important – a key driver for the introduction of authentig.

Find out why they chose authentig and what their goals were.

Flexibility thanks to the modular design

authentig is not a rigid system, but has a modular structure – which means maximum flexibility. You can start with a solution that is customised to your needs and expand it step by step as required. This means that the system can be tailored to individual requirements and future developments.

See how the modular design contributes to digitalisation step by step.

Transparency and documentation in production at the touch of a button

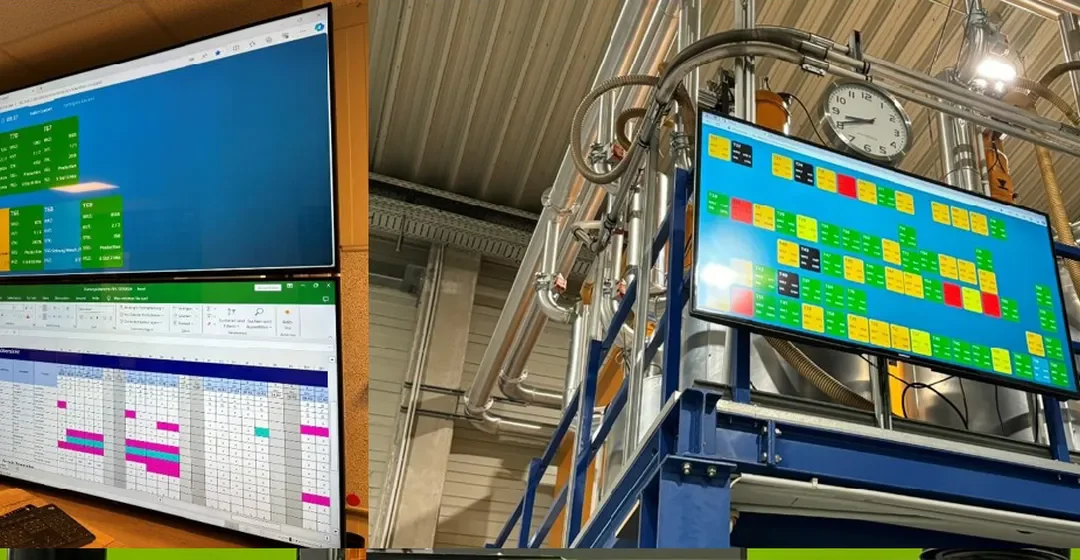

With authentig, a large number of process parameters per machine can be tracked seamlessly – at any time and on an order-related basis. Changes to the process can be traced back precisely, downtimes are documented with a time stamp and the machine status can be viewed live. The setup module in particular ensures that only authorised data records are used. Errors due to incorrect settings are a thing of the past.

Find out how authentig creates transparency in production and strengthens process stability

MES authentig in use: results and findings from the field

What are the concrete benefits of the authentig production control software? The figures speak for themselves: Hagleitner has been able to reduce machine downtimes by 7% and planning times by 15%. Thanks to intelligent limit value monitoring, operators receive early warnings long before the machine stops. Despite growing demands, the number of rejects has been kept stable.

At BIC, thanks to the MES authentig, problems in the injection moulding process aresolved based on data-based decisions and no longer on gut feeling. Shift managers can get a transparent overview of the status of production over the last seven days in just 15 minutes. Irregularities in process stability are registered in real time, thus preventing rejects.

Since the introduction of authentig, the production management software at KROSCHU has networked 34 injection moulding machines.Operating and machine data is recorded and machines are analysed automatically. The result: 9% increase in OEE.

Watch the video to find out what measurable benefits authentig delivers in everyday productio

Conclusion: authentig as a guide to efficiency and transparency in production

The Manufacturing Execution System (MES) authentig offers numerous advantages for modern production. The integration of real-time information and flexible customisation options significantly increase transparency in production.

Here is an overview of the main advantages:

-

Transparent production: authentig gives companies a complete overview of their manufacturing processes. Real-time information makes it possible to make data-driven decisions and react quickly to changes.

-

Seamless traceability: Every process change can be tracked precisely. This is particularly important in industries where product documentation requirements are crucial.

-

Modular structure for maximum flexibility: The system can be customised to the company’s needs and expanded at any time. This enables step-by-step digitalisation and adaptation to future requirements.

-

Process optimisation and increased efficiency: Early warnings of irregularities in the process can reduce downtimes and avoid rejects. This leads to an increase in OEE.

With authentig, the digitalisation of production is sustainably supported and becomes a real competitive advantage. The practical reports show that companies that implement authentig benefit from a cost advantage.

Injection magazine

You can view the document directly on the page. If you wish to download it, please enter your email address:

Neofyton is here for you

Have a question, need advice, or want to learn more about our solutions? Our team is at your disposal! Fill out the form below, and we’ll get back to you as soon as possible.

Your success is our mission.