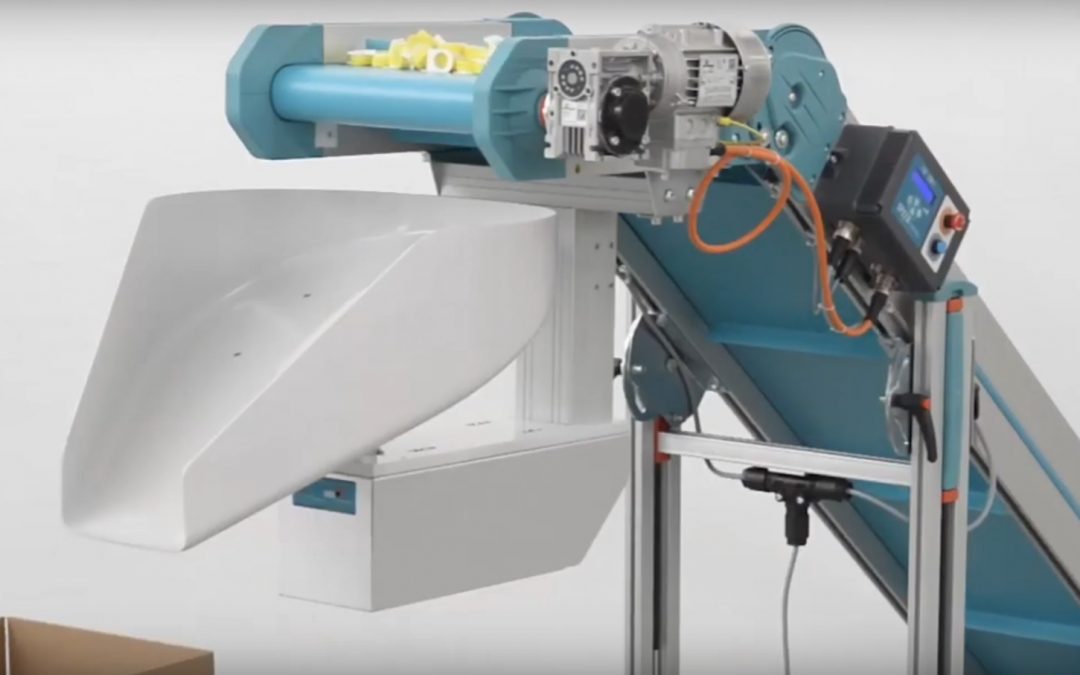

The N-Duck dispenser is specifically designed to be integrated onto MB conveyors and become part of it.

Its chute has a total rotation range of 240 ° (+/- 120 ° off the longitudinal axis of the conveyor),

and within such range it is possible to set the desired unloading points, always at the same distance from each other,

using the control panel installed on the conveyor.

HOW IT WORKS

All N-Duck dispenser functions are managed, as a standard, by an MB Base Control panel, where it is possible to set:

– Number of unloading points

– Product filling modes:

• IMM cycle count

• Timed filling

ALARMS

If during chute rotation an obstacle is found, the device stops immediately and the word “ALARM DUCK”

appears on the display.

Once the obstacle is removed, pressing “RESET ALARM” button the filling is resumed from where it stopped

NOTE: For technical reasons, N-Duck installation is only recommended within a specific dimension range

( i.e. A= min 240 mm, max 340 mm)

For more on MB Conveyors system and solutions, contact us

Neofyton – Company headquarters

Address – Partizanska 27b 21000 Novi Sad, Serbia

E-mail – info@neofyton.com

Phones

+381 21 452 642 +381 21 472 32 48

www.neofyton.com

General Manager – Zoran Tadic, dipl.ing. Msc.

E-mail – zoran.tadic@neofyton.com

Sales Director – Pedja Sandic

E-mail – pedja.sandic@neofyton.com

Phones

+381 64 6138226 Serbia

+385 912 227 883 Croatia

+2348147352823 Nigeria