Neofyton Service

ENGEL care – preventive maintenance for higher reliability and lower costs

Flexible packages from quick inspection to full proactive maintenance. Shorter planned downtime, earlier fault detection, and longer equipment lifetime.

Key benefits

Cost control

- Predictable costs instead of emergency call-outs.

- Preventive measures avoid major damage and costlier failures.

Safety and compliance

- Inspection of safety-critical parts and functions.

- Preserved machine functionality over the long term.

Operational reliability

- Shorter planned downtime.

- Smoother production and delivery planning.

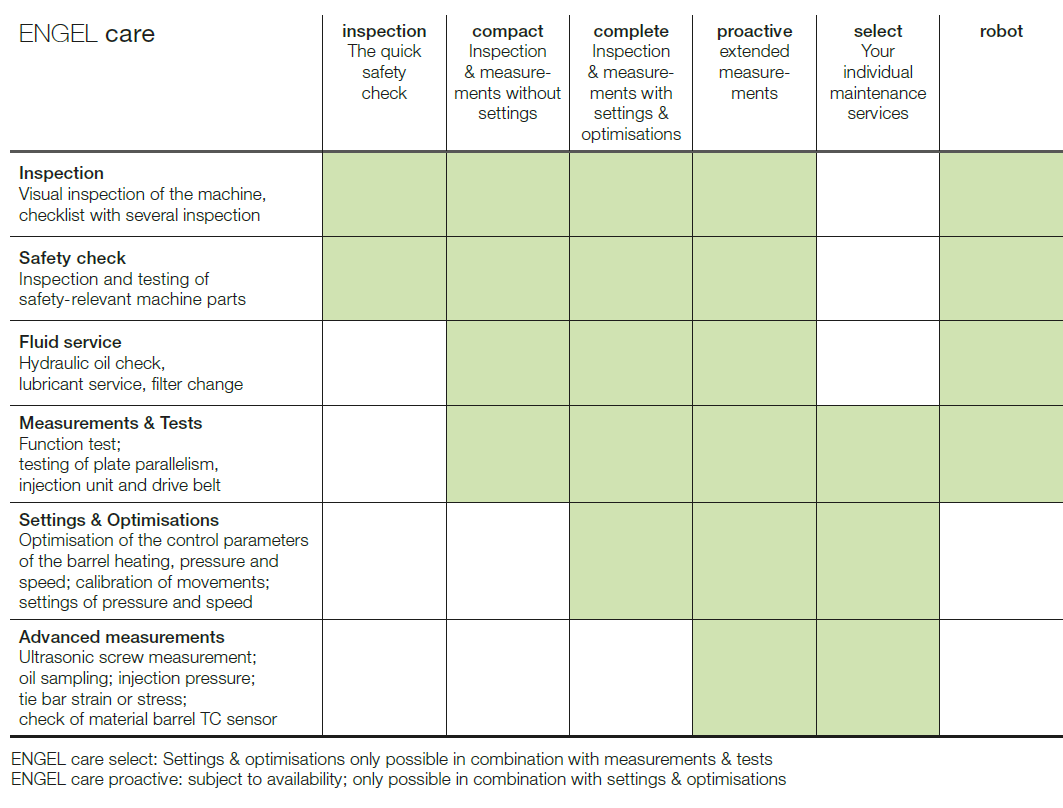

ENGEL care – maintenance packages

care inspection

- Quick safety check with checklist.

- Documented findings and recommendations.

care compact

- Functional tests and basic measurements.

- Parallelism, injection and drive checks.

care complete

- Measurements plus adjustments/optimizations.

- Calibration and fine-tuning of parameters.

care proactive

- Advanced diagnostics: screw ultrasound, oil sampling.

- Tie-bar strain measurement, TC sensors.

Note: “proactive” is typically combined with a package that includes adjustments (e.g., complete).

care select

- Individually selected activities as needed.

- Combine measurements and optimizations.

care robot

- Robot inspection and function check.

- Documentation of the as-is condition.

When, why and how to perform ENGEL care

When?

| Trigger | Recommendation |

|---|---|

| Annual service cycle | Usually 1× per machine per year (or more often for 24/7 operation). |

| Operating hours / age | Intensive use, >6,000 h per year or machines older than 5–7 years. |

| Process signals | Quality drop, clamp force fluctuations, rising energy use, frequent alarms. |

| Change of mould/material | Before switching to demanding moulds/materials (e.g., filled, abrasive). |

| After an incident | Following a breakdown, overload, or unplanned stoppage. |

Why?

- Reduce unplanned downtime and consequential failures.

- Maintain motion accuracy and process stability (part quality).

- Transparent, planned costs and better machine utilization.

- Safety compliance and extended equipment lifetime.

What the process looks like (5 steps)

- Planning: timing aligned with production (breaks, weekends, night shifts).

- Preparation: clean areas, access, technical docs and alarm history.

- Inspection & measurements: per selected package (inspection/compact/complete/proactive).

- Adjustments & tests: calibrations, trial cycles, parameter validation.

- Report & recommendations: findings, risks, replacement and optimization plan.

Case study: BARLOG Plastics

Results summary

- Unplanned downtime reduced to rare incidents with planned service windows.

- More stable cycle and more accurate clamp force after motion calibration and cylinder heating optimization.

- Better part quality: fewer parameter corrections and rework after start-up.

- Transparent machine condition thanks to detailed documentation and component-level findings.

- Predictable maintenance costs and simpler capacity planning.

Indicators – before vs. after

| Indicator | Before | After | Note |

|---|---|---|---|

| Equipment availability | Frequent short stops and ad-hoc service calls | Planned service windows; fewer incidents | Aligned with the production schedule |

| Process stability | Cycle time and clamp force fluctuations | Uniform cycle after calibrations | Plate parallelism and drive checks |

| Product quality | Occasional parameter changes and rework | Stable parameters; fewer changes | Fine-tuning of pressure/speed |

| Cost planning | Unplanned expenses for emergency interventions | Predictable costs per maintenance plan | Recommended replacement plan for wear parts |

| Condition visibility | Fragmented records | Complete report with recommendations | Documentation per machine/component |

Note: Exact figures vary per machine and load; the above summarizes observed changes after inspection, measurements and adjustments.

Activities performed

- Inspection of safety-critical parts and function checks.

- Measurements: function test, plate parallelism, injection and drive.

- Adjustments and optimizations: cylinder heating, pressure and speed; motion calibration.

- Advanced diagnostics (as needed and available): oil sample, screw ultrasound, tie-bar strain, TC sensors.

- Condition report and recommendations for next service steps and replacements.

Ready for more reliable production?

Request a proposal for an annual preventive maintenance plan for your ENGEL machines and robotic systems.