by Dušan Bunović | 24. 02. 2021. | News, Partners

How can consistently high product quality be maintained in the face of fluctua-tions in raw material? How can high machine availability and productivity be ensured even in the face of travel restrictions? – ENGEL will be providing an-swers to these burning questions...

by Dušan Bunović | 23. 02. 2021. | News, Partners

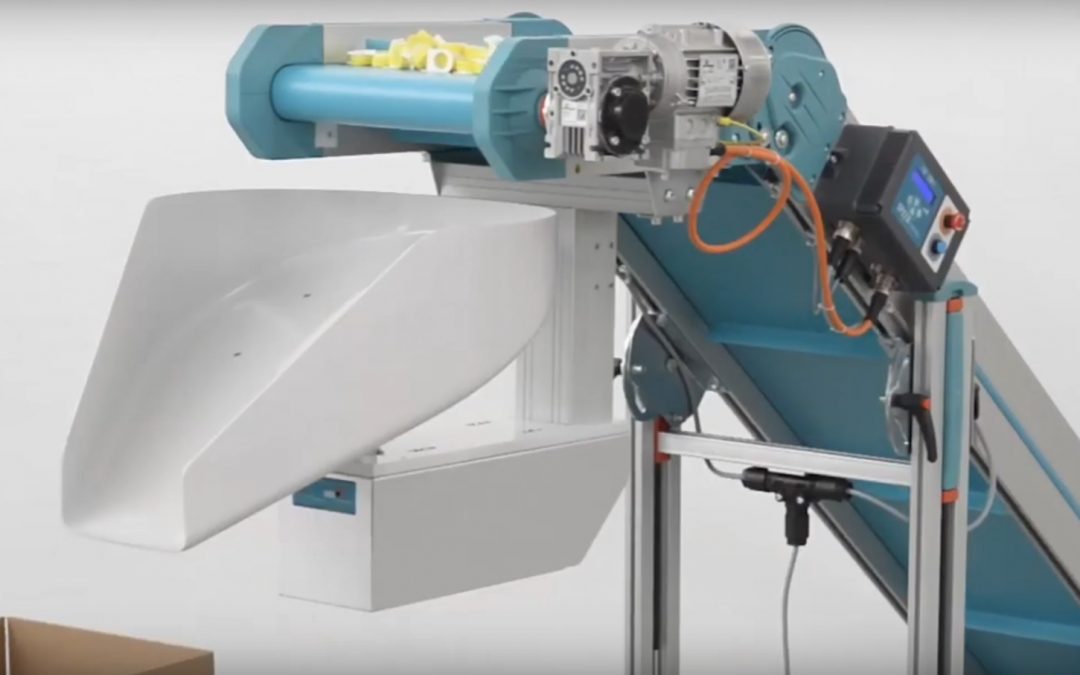

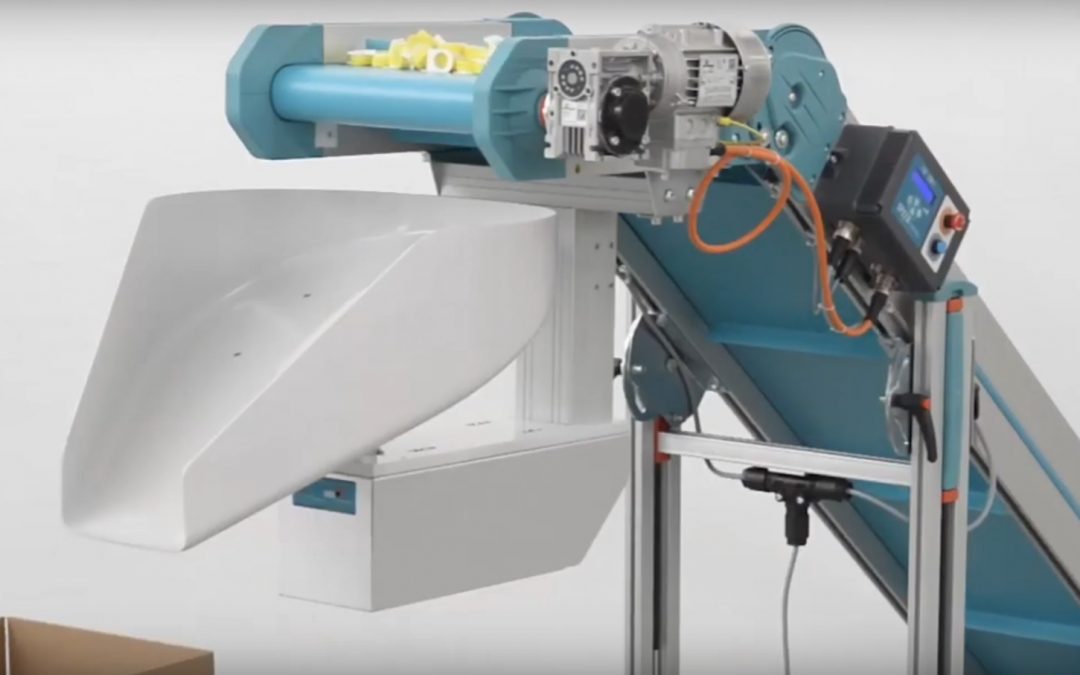

The N-Duck dispenser is specifically designed to be integrated onto MB conveyors and become part of it.Its chute has a total rotation range of 240 ° (+/- 120 ° off the longitudinal axis of the conveyor), and within such range it is possible to set the desired...

by Dušan Bunović | 19. 01. 2021. | News, Partners

WINTEC, a member of the ENGEL group of companies headquartered in Austria, is expanding sales of t-win injection moulding machines to Europe. This step makes the dual-platen large-scale machines available worldwide. With a tradition lasting 28 years, admirable...

by Dušan Bunović | 18. 01. 2021. | News, Partners

ENGEL presents – the first injection-moulded bicycle frame with advanced thermoplastic composites and a hollow closed tube geometry. It was developed over the last five years in co-operation with V-Frames, Plastic Innovation GmbH and Johannes Kepler Universität...

by Dušan Bunović | 22. 12. 2020. | News, Partners

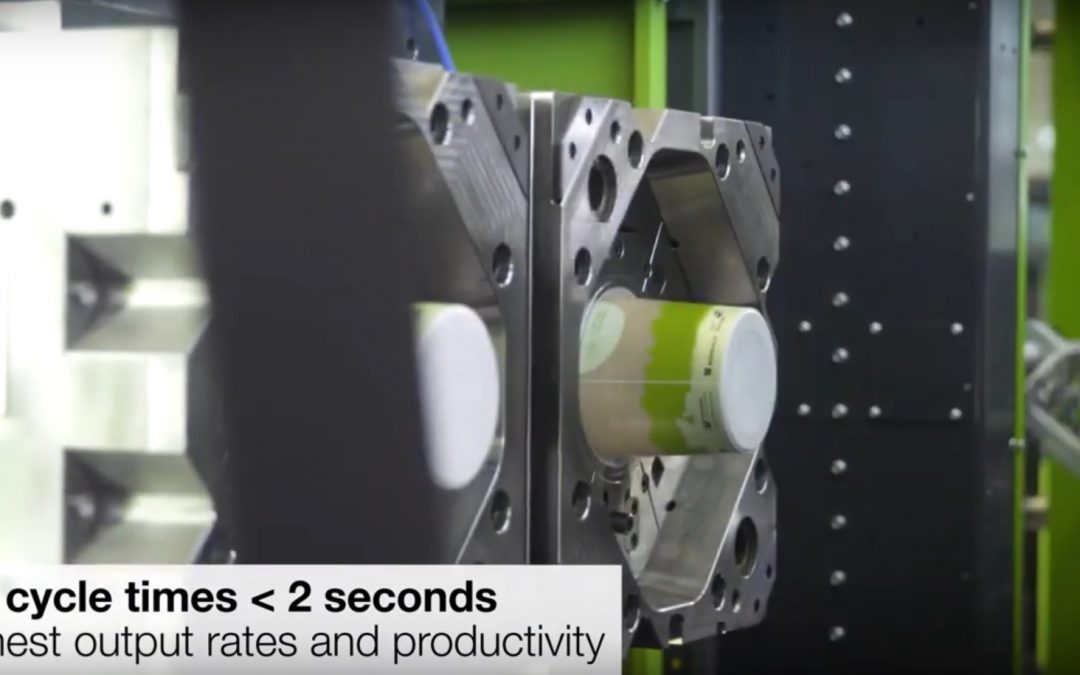

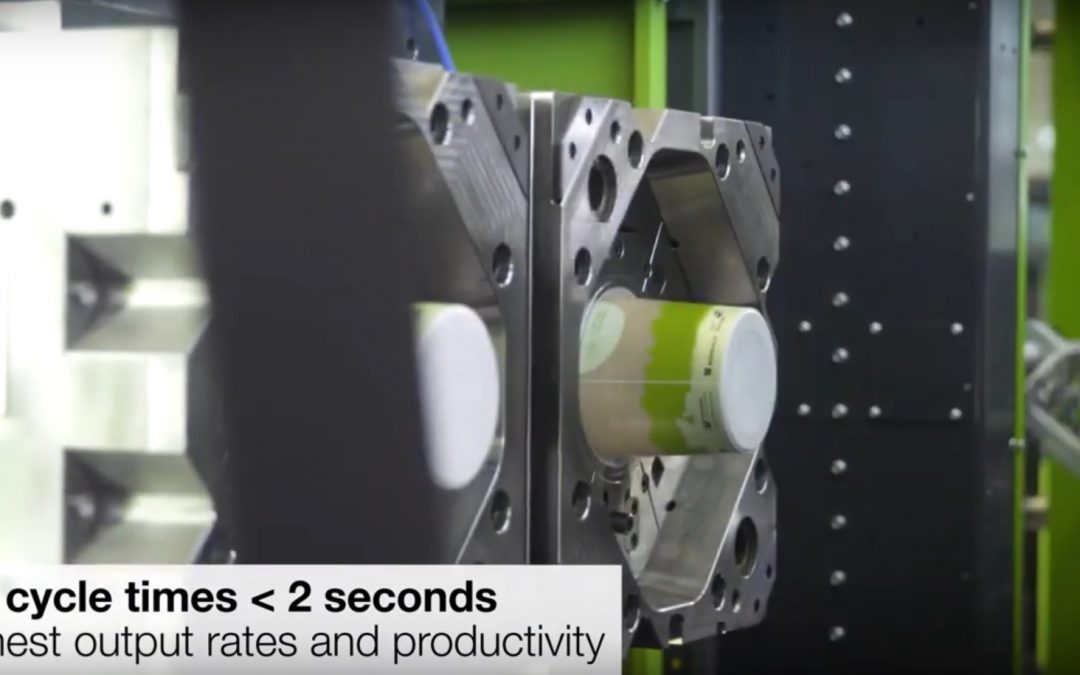

ENGEL e-speed 280 for packaging. Production of 1 L bucket with IML High performance hybrid injection molding machine. Industry – Food packaging Clamping force – 2800kN Injection unitst – Hydraulic high performance injection unit 70 Dry cycle –...

by Dušan Bunović | 16. 12. 2020. | News, Other news, Partners

iQ flow control by ENGEL ensures consistent precision and lower unit costs at Blum Temperature control, not watering The light grey tubes, which are inconspicuous at first sight, are really critical. They enclose a sensitive mechanical system which, in kitchen...