Small footprint & maximum efficiency

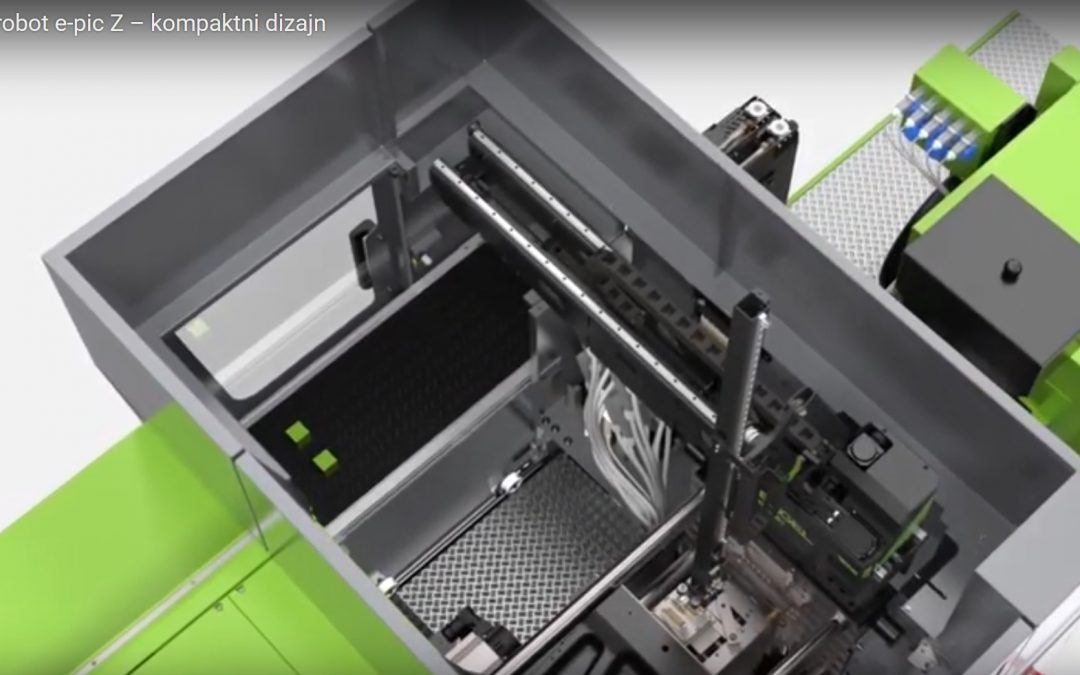

The swivel-arm kinematics make the system highly compact and saving space by integration

into the injection moulding machine.

The e-pic Z can also used as stand-alone robot.

ust plug it in, turn it on and get started: the new ENGEL e-pic Z offers a cost-effective and energy efficient introduction to automation

It facilitates fast, safe and simple manipulation of the parts and, along with short intervention times, a trouble-free production process. An added bonus: thanks to its newly developed kinematics, the e-pic Z is highly compact and can be integrated into the injection molding machine without occupying much space.

- universally applicable – flexible pick and place robot fits in all machines up to 220 tons

- compact design – can be fully integrated into the ENGEL injection molding machine – no need for a control cabinet

- optimum efficiency – economical entry-level model with low acquisition costs and minimum operating costs

- short cycle times – high performance thanks as a result of weight-optimized design and new kinematics

- user-friendly operation – easy and safe operation as a result of data synchronization of the RC16 with the IMM (CC300) – no programming skills required

- full standard equipment package – C-axis, 2 pneumatic lines and 2 lines that can be switched from vacuum to compressed air, 8 additional customizable I/O ports

Neofyton is Engel partner for the sale and installation of

Engel plastic injection molding machines for the markets of Serbia,

Bosnia and Herzegovina, Macedonia, Croatia, Montenegro, Nigeria, Cameroon and Ghana ,

as well as equipment for the plastics industry of Piovan, Sipa, Tria, MB Conveyors and Eurochiller .