K 2025 • ENGEL e-mac 220 • 100% PCR

Compact foaming concept with major material savings

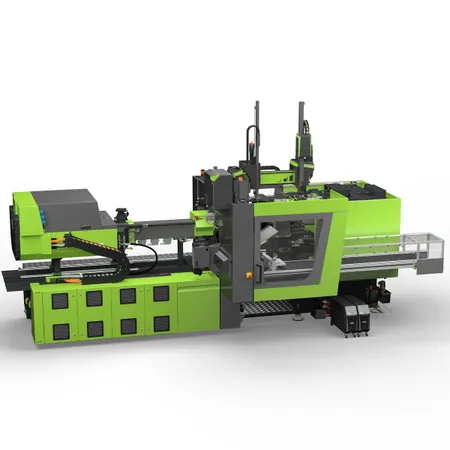

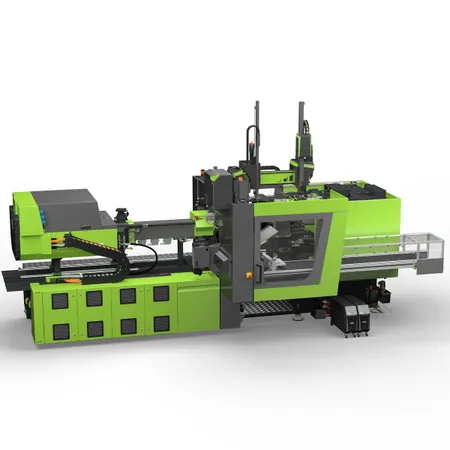

At K 2025, ENGEL will demonstrate how maximum sustainability, cost efficiency and floor-space savings merge into a single production cell. The focus is on foaming material in-mould for technical parts made from 100% post-consumer recyclate (PCR), on a minimal footprint and with a fully automated process.

Application & concept

Rugged yet lightweight components – a practical substitute for concrete in manholes and similar uses.

This ENGEL cell is ideal for producing robust, lightweight parts that are easy to handle – for example, as a replacement for concrete components in construction. The heart of the setup is the all-electric e-mac 220 (2,200 kN) which, on a minimal footprint, produces thick-walled and durable parts from PCR, with precise foaming and full automation. For show context, see K 2025 – Neofyton.

Foaming process & materials

The ENGEL foammelt technology uses a blowing/expanding agent and, combined with a purpose-designed Moxietec additive blend, creates a homogeneous, fine-cell structure. The result is lower weight and higher stability. In the showcased application an ~30% mass reduction was achieved at a shot weight of ~538 g, along with +10% higher impact strength.

The process runs on post-consumer recyclate (PCR) from the “Gelber Sack” system, collected by PreZero and reprocessed to high quality by EREMA. Foaming is enabled by a Moxietec additive/agent blend, complemented with Vistamaxx (ExxonMobil). A gravimetric Movacolor dosing system ensures extremely uniform cell distribution – critical for thicker walls where conventional physical foaming approaches reach their limits.

Plasticizing & melt quality

The standard ENGEL screw ensures homogeneous melting of granulate. Decompression after dosing can be omitted entirely, reliably preventing air entrapment and sink marks. This is enabled by a ring-type non-return valve with a new geometry: crowned valve wings improve repeatability and, in the short-stroke version, provide clearly faster closing.

The digital assistant iQ melt control analyzes plasticizing during sampling and suggests optimal parameters (screw speed, back pressure, dosing stroke). This maintains consistent part size and maximizes material efficiency. Chilled nozzle tips support the desired level of foaming. With a Moxietec 2-cavity mould, the e-mac cycle is around 120 s.

Mould tempering with iQ flow control

For thick-walled parts, tempering is crucial. The latest e-temp units operate with water at just 90 °C, without special hot-water installations – lowering operating costs. iQ flow control digitally monitors and dynamically regulates flows; together with e-temp devices the system instantly detects and automatically corrects deviations. The result is uniform cooling, minimal warpage and better dimensional accuracy. Optimized flow control also reduces energy consumption for tempering.

Automation & compact layout

The cell is designed compact: a servo sprue picker removes the runner while the ENGEL viper 12 linear robot extracts the part and places it on the conveyor integrated within the safety fence. Automation is fully integrated into the machine control and iQ motion control optimizes motion profiles – shortening cycle time and reducing energy usage.

Sustainable lightweight solution: e-mac 1565/220

The all-electric e-mac 220 produces locking block elements from 100% PCR in a fully automated process. Parts are further expanded by combining Moxietec technology with ENGEL foammelt, reducing material consumption by ~30% while achieving +10% higher impact strength.

Technical details of the production cell

| Application | Locking Block |

|---|---|

| Clamping force | 2,200 kN |

| Injection unit | 1565 |

| Screw | Ø 70 mm, Standard Mixing Screw SMS G13, L/D 20 |

| Mould | Moxietec (2 cavities) |

| Material | Post-Consumer Recyclate (PCR) |

| Technologies | ENGEL foammelt & Moxietec Foam Injection Moulding |

| Automation | ENGEL viper 12 & ENGEL servo sprue picker (X-axis) |

| Cycle time | ~120 s |

| Shot weight | ~538 g |

See you at K 2025!

Düsseldorf • Hall 15 • Stand B42 & C58

Frequently asked questions

What is ENGEL foammelt and what makes it specific?

Foammelt is a process in which a blowing agent is introduced during injection. Combined with suitable additives, it forms a fine-cell structure, lowers weight and maintains/increases part robustness.

What is the role of iQ melt control?

It analyzes plasticizing during sampling and suggests optimal parameters (screw speed, back pressure, dosing stroke) so that material for foaming recyclates is prepared as consistently as possible while maximizing material efficiency.

Which parts is this solution best suited for?

Rugged yet lightweight components – e.g. elements that can replace concrete in manholes, or other technical parts where the strength-to-weight ratio is critical.

K 2025 – additional information

K 2025 – Düsseldorf, 8–15 October

You are invited to meet Neofyton and our partners at the world’s leading plastics and rubber trade fair.

Together we will present innovative solutions in injection moulding, automation, digitalization and sustainable production.

We look forward to meeting you and discussing your projects.