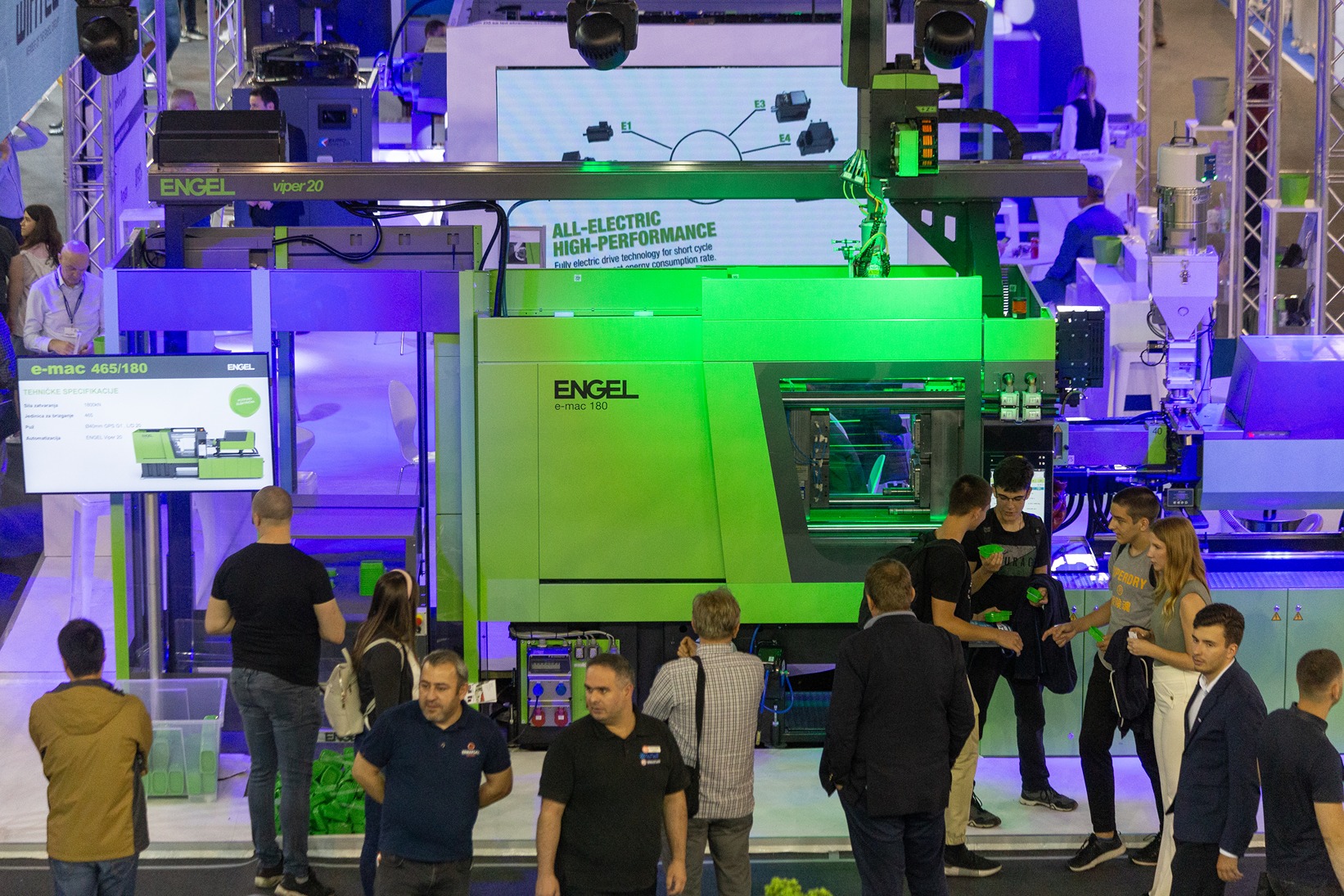

At the International Fair of Technique and Technical Achievements, held from May 20 to 23, 2025, in Belgrade, Neofyton once again confirmed its position as a technological leader in the plastic industry solutions market. At the highly visited booth 3022 in Hall 3, we presented a fully automated production unit developed in cooperation with global partners: ENGEL, Wintec, Piovan, and Oerlikon HRSflow, with the support of Inmold, Drina Plastika, Texaco, and Vračar IML.

A Production Unit Without Compromise

Our production system showcased the most advanced solutions in automation, injection molding, and quality control—operating entirely without manual labor. Innovations from the following global brands were featured at the Neofyton booth:

🔹 ENGEL AUSTRIA GmbH – A global leader in plastic injection moulding machines, with a focus on automation and digitalisation. The latest generation e-speed 280/70 WP machine was showcased, specially designed for demanding packaging applications, offering impressive speed and precision. With a clamping force of 2800 kN, the e-speed demonstrated highly profitable thin-wall packaging production, thanks to its optimal flow length-to-wall thickness ratio. It is suitable for processing a wide range of polymers—from standard applications like cups, lids, and containers to complex systems and demanding materials. At the fair, a 1.3-litre food packaging container was produced using IML (In-Mould Labelling) technology on this machine.

This complex setup resulted in a finished, visually branded product made in a real production cycle of just 5.5 seconds, with zero manual operations—fully demonstrating the power of modern industrial automation and digital process monitoring.

🔹 WINTEC(a series by ENGEL) – A brand aimed at customers seeking reliability and standardised machines with excellent price-performance ratios. The displayed t-win machine had a clamping force of 4500 kN, equipped with a viper 20 robot for product handling and a mould simulating real production conditions—a flowerpot of 8 litres.

🔹 PIOVAN Group – A leading manufacturer of equipment for automatic dosing, drying, conveying, and recycling of plastics. Visitors saw a complete central system for granulate preparation and transport, integrated into the demonstration process.

🔹 OERLIKON HRSflow – A specialist in hot-runner systems, focusing on energy efficiency and reliability when working with complex moulds. Their advanced technology was presented through hot nozzles integrated into the mould on the ENGEL e-speed 280/70 WP machine. This configuration enabled optimal material injection, uniform flow across all cavities, and high product quality—particularly important for thin-walled packaging produced with IML technology.

The successful realization of the fair presentation and machine demonstrations included:

🔹 Drina Plastika, a reliable manufacturer of plastic household products, whose item was produced live during the fair

🔹 Inmold, which supplied the high-precision mold and IML-function robot

🔹 Vračar IML, which prepared the labels for the IML process

🔹 Texaco, which provided industrial oil for optimal machine performance throughout the presentation

This collaboration enabled visitors to witness a complete production process—from raw material to a finished, labeled product—meeting the highest technological and quality standards.

Industry in Motion – Digital Transformation and Sustainability

Beyond technical innovations, special attention was given to topics of digitalisation and sustainable development, through concrete examples of digital platforms for real-time monitoring, control, and optimization of production parameters. Presented solutions included:

-

Reduced energy consumption

-

Predictive equipment maintenance

-

Precise resource management

-

Integration of recyclates into the production process

Neofyton and partner experts held a series of informal consultations with visitors on digital transformation, use of recycled materials, and strategies for improving competitiveness through smart solutions.

Visit from Dr. Stefan Engleder

We were especially honored to welcome Dr. Stefan Engleder, CEO of ENGEL Austria, who personally visited our booth and expressed satisfaction with the level of integration and professionalism on display. His visit to Belgrade was more than a formality—it was a strong signal of ENGEL’s strategic commitment to the Southeast European market and a confirmation of its long-standing partnership with Neofyton.

He particularly emphasised the importance of international cooperation and local expertise in implementing modern solutions, as well as Neofyton’s role as a regional integrator and driver of digital transformation in the plastics industry.

Our booth was hosted by Mr. Zoran Tadić, General Manager of Neofyton and Honorary Consul of the Republic of Austria in Vojvodina, who, along with partners, presented past achievements and directions for future cooperation.

Award for Best Technological Innovation

For this presentation, Neofyton received the prestigious award from the Fair for the Best Technological Innovation—a result of months of dedication from the team and all project partners.

The Power of Partnership

We thank all partners and collaborators who contributed to this success: ENGEL, Wintec, Piovan, Oerlikon HRSflow, Inmold, Drina Plastika, Texaco, and Vračar IML. Together, we are building the industry of the future—faster, more precise, and more sustainable.

A Vision for the Future

This event was more than a product showcase; it was a demonstration of a clear vision: digitised, energy-efficient, and fully automated production as the foundation of modern industry. Neofyton is proud to lead this transformation.

Thank you to everyone who visited and participated in this great shared success!