WINTEC machines, originally made for the Asian markets, are now sold across the globe.

The machines are designed to offer both standard and high-performance solutions to cover different market needs. Supporting a wide range of applications has consolidated WINTEC’s status as a dependable partner in plastics processing.

Ten years of shared success

WINTEC celebrates anniversary

Last September, we marked a significant occasion at our plant in Changzhou: the 10th anniversary of WINTEC. Celebrating “ten years of shared success”, the event brought together staff, partners and customers to look back on a positive and productive decade. Ever since it was founded in 2014, WINTEC has been a cornerstone of the ENGEL Group, and it now maintains a global presence with over 1,000 machines sold around the world.

Technological developments mark anniversary year

As part of its anniversary celebrations, WINTEC unveiled its new t-win pro and e-win pro machine series.

The t-win pro is a dual-platen injection moulding machine that benefits from ENGEL’s extensive expertise in this field. It includes an energy-saving drive system for strong performance, which also allows for quick cycle times and long lifespans. Despite their space-saving design, this machine offers convenient access to the mould and to important components. This makes it easier and faster to carry out mould changes or any maintenance work. The t-win pro is available with clamping force levels from 400 to 4,000 tonnes.

The all-electric e-win pro machine series provides impressive results thanks to its precision and its energy use is sparing on account of its highly efficient servo-motors. The new plasticising units can be swivelled out for maintenance tasks, making access significantly easier and keeping standstill times to a minimum. The high-stability frame-based design supports the machines’ high levels of precision and longevity. They are already available in Southeast Asia with clamping forces ranging from 100 to 380 tonnes.

Both series were developed to support more efficient and sustainable production processes. The developments form part of WINTEC’s continual efforts to offer customers around the world solutions that are practical and cost-effective.

“For 10 years, WINTEC has been part of the ENGEL Group. Looking forward, it will play a vital role in ensuring our success over the long term. Today we not only serve local markets, but also maintain a global presence through WINTEC. As a brand, WINTEC stands for delivering accessible innovations, which means we create access to innovations for particularly cost-conscious customers – with a focus on certain solutions, including in the automotive sector and technical injection moulding,”

says Stefan Engleder, CEO of the ENGEL Group, on the development of the WINTEC brand.

Capacity expanded in Changzhou

Expansion of its Changzhou site has enabled WINTEC to significantly upscale its research and development capacity. As a result, the company is able to respond faster to local market needs and offer custom solutions to meet the particular requirements of customers in various regions.

Strengthening local production and expanding capacities have been critical steps in enabling us to carry on delivering efficient, high quality machine solutions.

“The expansion of our site in Changzhou has enabled us to upgrade our research and development capacities and increase the production of standardised, high performance injection moulding machines. This puts us in a position to respond even faster and more efficiently to developments on the local market, thereby addressing the growing demands of our customers. At the same time, we are offering made-to-measure solutions in various regions and thereby improving the support we can provide on site,”

explained Gero Willmeroth, Regional President Asia and Oceania.

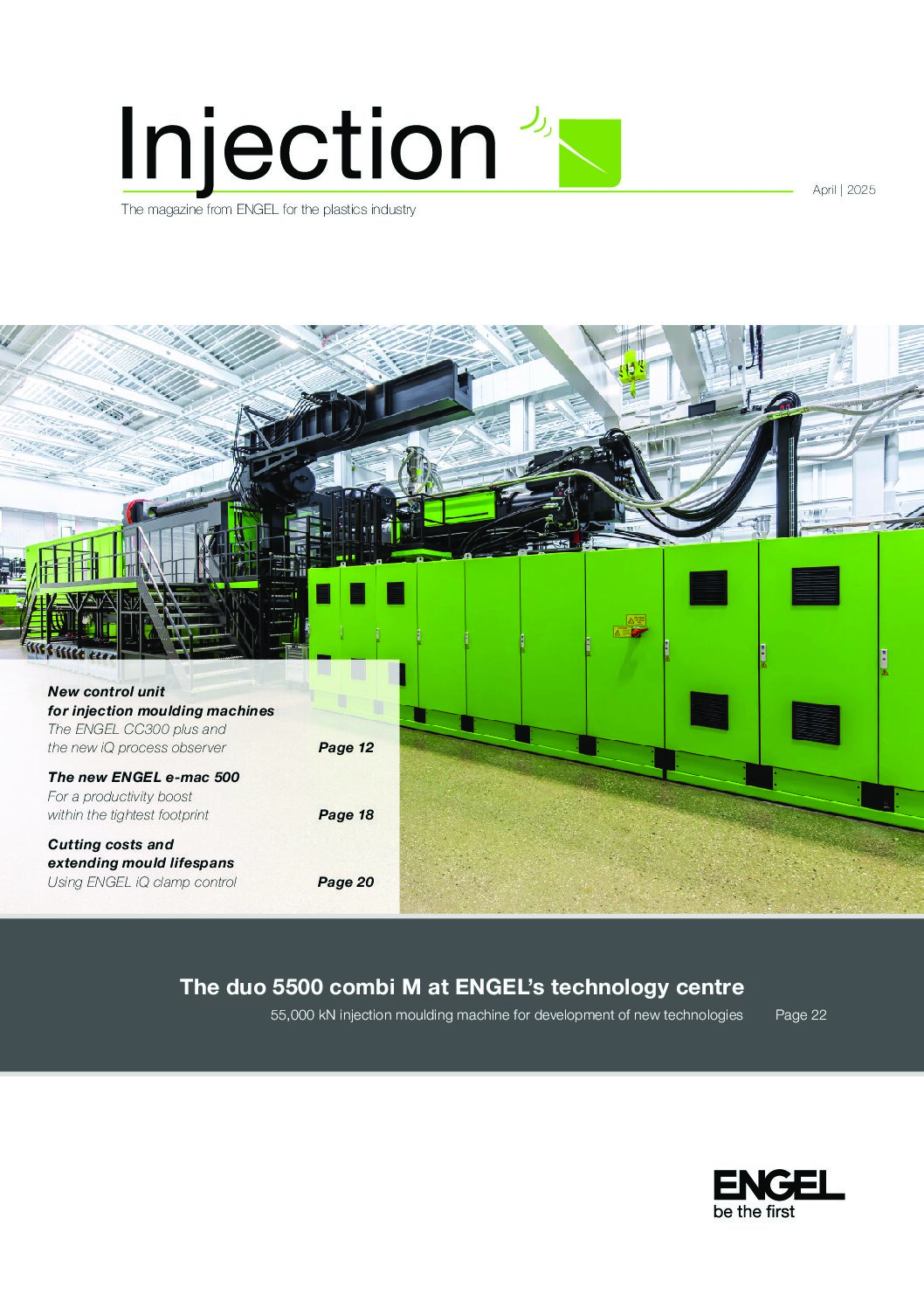

ENGEL Injection E-Paper | April 2025

The magazine from ENGEL for the plastics industry

Our customer magazine “Injection” combines news from the ENGEL world, updates from our subsidiaries, tech articles on the latest product developments and success stories from our customers.

On 36 pages the current issue covers the following topics & more:

- The new ENGEL e-mac 500: For a productivity boost within the tightest footprint

- Cutting costs and extending mould lifespans: Using ENGEL iQ clamp control

- The duo 5500 combi M at ENGEL’s technology centre: 55,000 kN injection moulding machine for development of new technologies