In October 2020, ENGEL is presenting the next generation of its all-electric e-mac injection moulding machine series

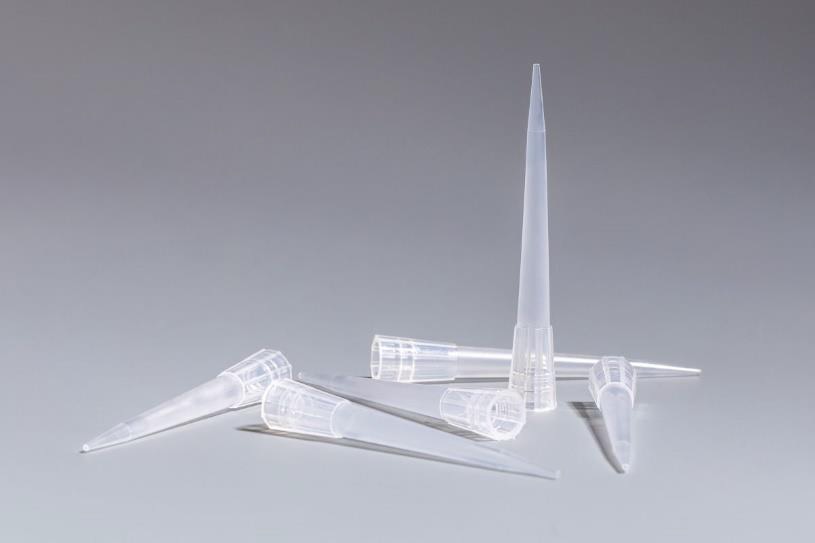

in a challenging application for the manufacture of pipette tips.

Offering maximum flexibility for individual cus-tomer requirements, the e-mac is now even more compact.

The quality of pipette tips largely depends on the precision of the injection process.

At the same time, the long cores in the mould require absolutely precise movements of the mould mounting platens

during opening and closing.

All-electric injection moulding machines are therefore the preferred solution in this application segment,

where cost-effectiveness is a de-cisive factor in choosing a machine. In the form of the e-mac,

ENGEL has an all-electric in-jection moulding machine in its portfolio that combines high output and energy efficiency

with an extremely compact machine design, ensuring the lowest possible unit costs

even in a clean-room environment.

ENGEL has now reduced the footprint of the e-mac machines even further.

Thanks to an optimised toggle lever geometry, the e-mac 265/180 presented for mar-ket launch is 450 mm shorter

than the previous 180-ton version, without reducing the open-ing stroke.

Among the all-electric machines on the market, the e-mac machines of the new generation

are the most compact worldwide in their respective performance segment across the entire series.

All movements of the ENGEL e-mac – including the nozzle movement and ejection – are per-formed

by servo-electric drives.

This means that the machine achieves very high overall effi-ciency.

If required, a servo-hydraulic unit can be integrated into the machine frame without requiring additional space.

Überschrift 2 über Schrift

Read more. Download Engel Press-release (English version)

Read more. Download Engel Press-release (German version)