For the first time worldwide, IMD in combination with thin-walled polycarbonate organo sheets.

Vertical injection molding machine for perfectly overmolded insert parts

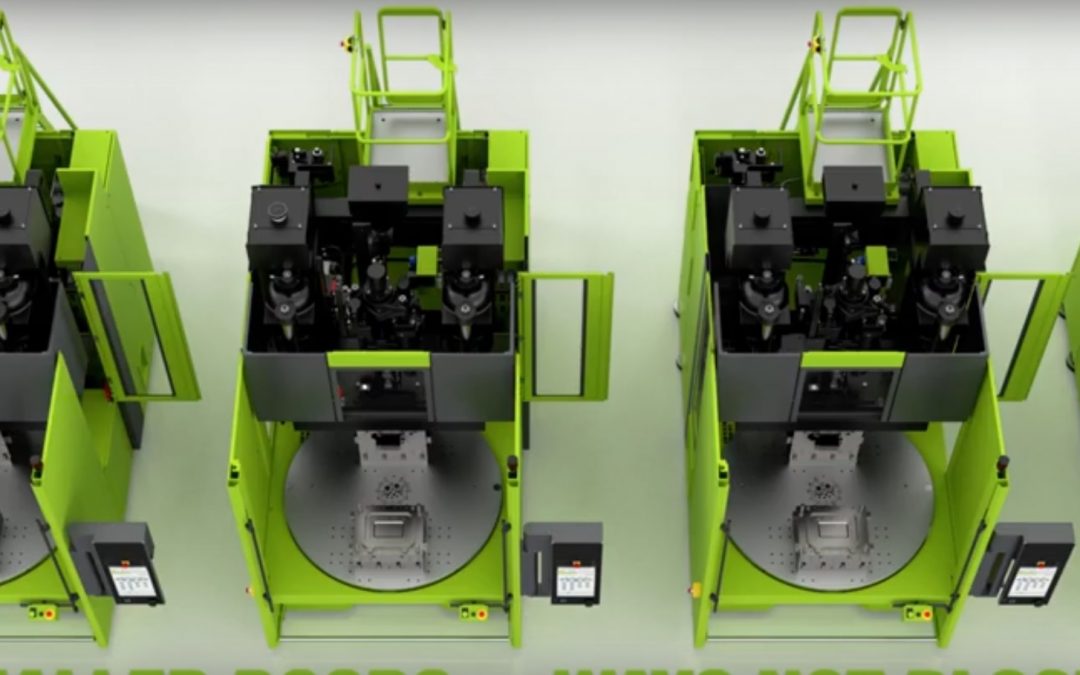

A compact, variable injection molding machine with vertical clamping unit – perfectly suited for precision molding of insert parts

in the process of overmolding inserts, precision is of utmost importance.

With its compact, variable machine concept and vertical clamping unit, the ENGEL insert is the ideal solution.

In order to meet every mold requirement, this model range is comes both

with a vertical and a horizontal injection unit.

Plus, as the ENGEL e-insert, available with a servo-powered, electric injection unit and featuring the i

nnovative hydraulic ENGEL ecodrive as a standard, it will achieve even more precision.

- individual injection molding machine – available in the single, rotary and shuttle variants, depending on the mold area requirements

- small footprint – ergonomically optimized working height without operator platform, short design especially in case of a vertical injection unit

- outstanding energy-efficiency – low friction, clamping pressure lock-in and electro-hydraulic control pump, ENGEL ecodrive

- easy accessibility – efficiently protected open work area by means of a light curtain

- clamping force – from 300 kN to 4,000 kN

Neofyton is Engel partner for the sale and installation of

Engel plastic injection molding machines for the markets of Serbia,

Bosnia and Herzegovina, Macedonia, Croatia, Montenegro, Nigeria, Cameroon and Ghana ,

as well as equipment for the plastics industry of Piovan, Sipa, Tria, MB Conveyors and Eurochiller .