THE TRADE FAIR SHAPING THE FUTURE OF THE PLASTICS INDUSTRY

K show, Düsseldorf, 8–15 October 2025

From 8 to 15 October 2025, Düsseldorf becomes the global hub for the plastics and rubber industry. K 2025 brings together leaders in innovation and technology – and we’ll be there with all our partners.

Expect smart solutions, sustainable technologies and concrete steps towards a circular economy. In one place you can see machines in action, meet experts and get answers to the challenges of modern manufacturing.

For more information, write to us at marketing@neofyton.com.

See you in Düsseldorf!

K 2025 – Düsseldorf, 8–15 October

We invite you to visit Neofyton and our partners at the world’s leading trade fair for plastics and rubber.

Together with our partners, Neofyton will showcase innovative solutions in injection molding, automation, digitalization and sustainable production.

We look forward to meeting you and discussing your projects.

Invitation Book a meeting

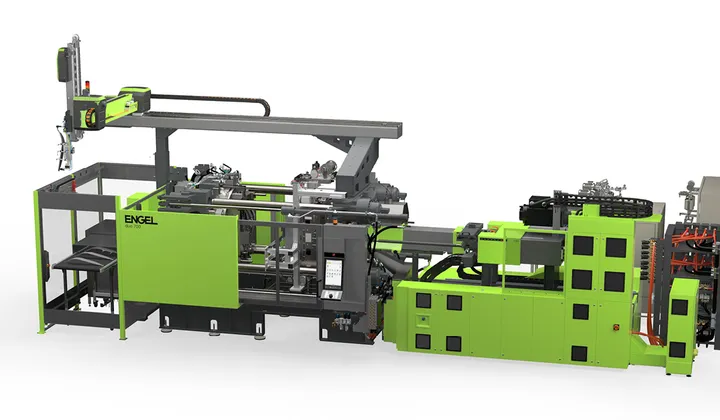

ENGEL exhibits

Hall 15 / Stand B42–C58

victory 180

- Tie-bar-less technology

- Polyamide bicycle handlebars

- ENGEL fluidmelt + UD tapes

e-motion 280 combi M

- Multi-component medical parts

- Cleanroom-ready solution

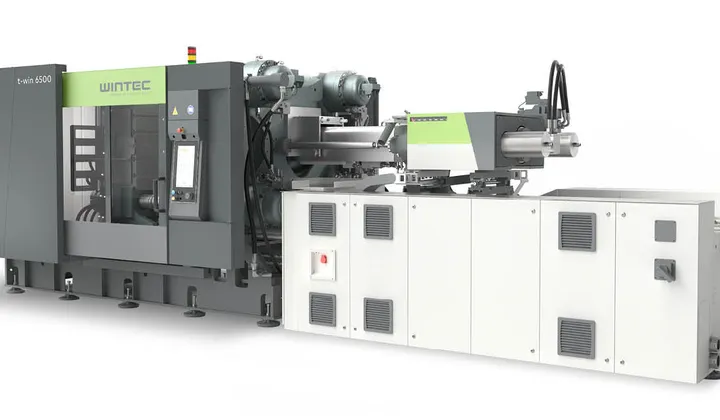

t-win 6500

- Large hydraulic machine for standard applications

- B-pillar covers for the mobility industry

- Foammelt

Video gallery from K2022

Expert Corner

Our specialists are available for advice, demos and first-hand experience with ENGEL technologies.

connect with ENGEL – inject 4.0

Live smart factory demo. Digital solutions across the entire product lifecycle: from design to production.

- iQ process observer – process monitoring

- authentig – user authentication

- part finder – spare parts identification

- sim link – design connectivity

- Set-up assistant – start-up support

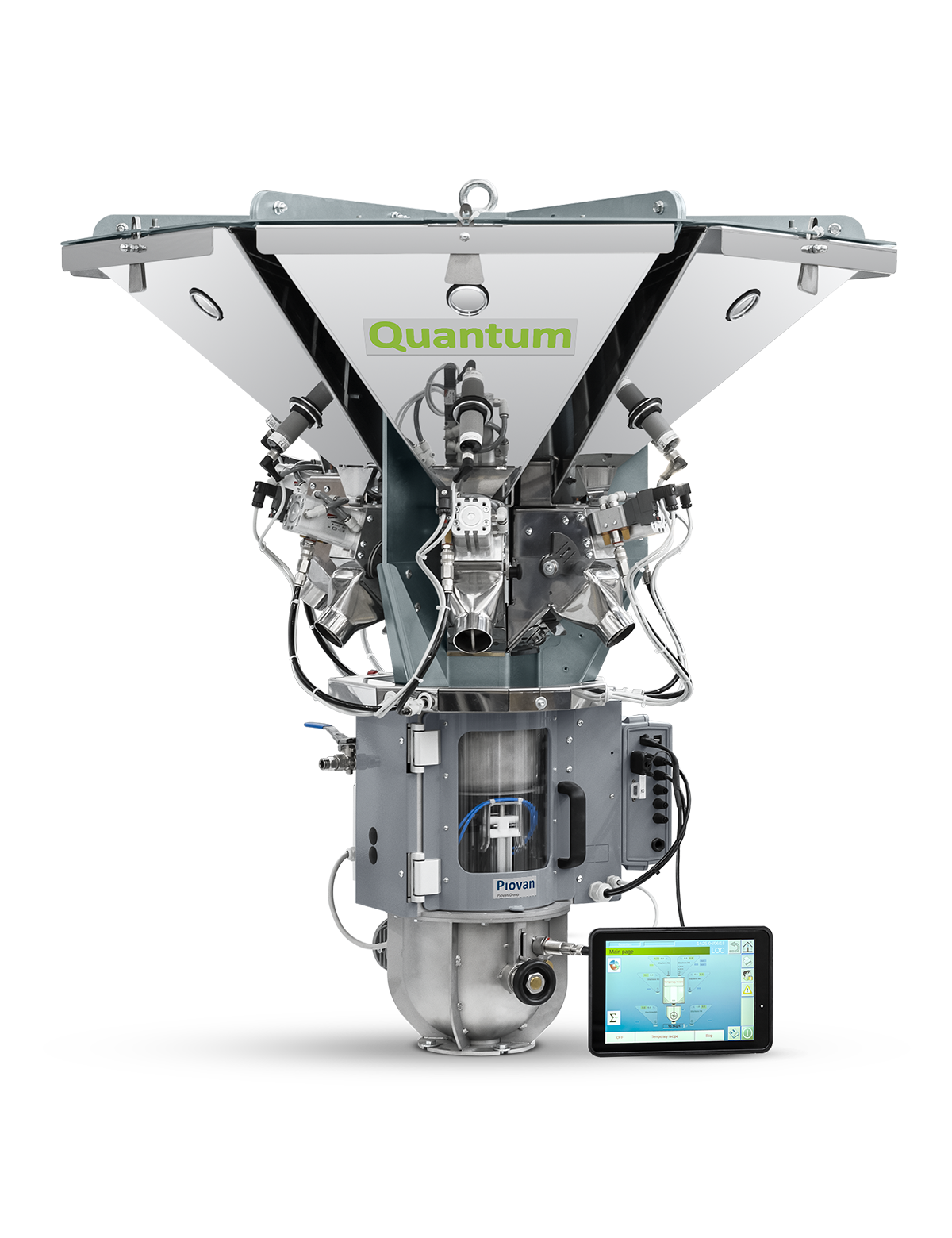

Piovan

Hall 10 / Stand C20

Solutions for drying, conveying and dosing materials, dust removal and recycling, complemented by digital platforms for process and energy monitoring.

- Central systems: optimal material and energy management

- High-repeatability dosing of colors and additives

- Integrations with injection molding machines and extruders

Oerlikon HRSflow

Hall 1 / Stand C72

At K 2025, Oerlikon HRSflow presents the latest innovations in hot runner systems for injection molds, with a strong focus on sustainability and improved energy efficiency.

Oerlikon – websiteMB Conveyors

Hall 10 / Stand E31

MB Conveyors will showcase a new generation of conveyor belts and automated handling systems developed to improve process efficiency.

MB Conveyors – websiteTRIA

Hall 9 / Stand D02

TRIA will display its latest granulators and plastic recycling solutions, emphasizing efficiency, compactness and reliability across different waste streams.

TRIA – websiteIFW

Hall 1 / Stand C15

ifw mould tec is pushing the boundaries of compact injection moulding production. At K 2025, the company will present its latest innovation – a 2K family mould with integrated assembly and leak testing. By combining multiple processes within one compact production cell, efficiency is significantly increased while the need for additional machines and stations is reduced.

The demonstration will take place on an ENGEL Victory 220t machine, featuring a three-stage process: moulding of PP base components, overmoulding of TPE sealing elements, and final assembly with leak testing – all within one compact cell.

IFW is synonymous with innovation and precision in the manufacture of moulds for pipe fittings. Its SE system (Smart Ejection) reduces clamping force requirements, allows more cavities in the same mould, and delivers energy savings of up to 40%. This technology has already become a global standard among customers.

Key benefits of IFW solutions:

- Compact 2K production – fewer machines and auxiliary stations, higher output per m².

- High degree of automation with virtually zero scrap rate.

- Modular mould concepts – fast adaptation to market demands and long-term investment security.

- Fast spare parts availability thanks to a high level of standardisation.

- ifw kunststofftechnik: flexible contract manufacturing on 20+ machines (120–3,200 t).

With its in-house development centre and state-of-the-art facilities, IFW remains a reliable partner and international leader in injection moulding technology.

IFW – websiteDownload IFW catalog

Free tickets

Secure your entry to K 2025

Neofyton can provide tickets for K 2025.

Click the button to fill in the contact form.

In the message, specify the number of tickets you need.

Note: The number of codes is limited – please request your tickets in time.

Location & Info

🗓 8–15 October 2025

🕘 Visitor opening hours: 10:00–18:30

Schedule a meeting with our team

Suggest a time or contact us for a tailored presentation.